Наш окончательный ответ на удобные и экономящие место потребности в водяном охлаждении - это Водяной Охладитель Под Раковину. Вы больше никогда не увидите громоздкий диспенсер для воды, загромождающий вашу столешницу! Эта новая система аккуратно помещается под вашей раковиной, чтобы предоставлять вам холодную воду, когда бы вы ни захотели, одновременно экономя место. У нее стильный вид и она хорошо работает для легкого поддержания гидратации благодаря своей эффективной технологии охлаждения. Освежите себя, переключившись на этот Водяной Охладитель Под Раковину, который не только сохраняет вашу кухонную декорацию нетронутой, но и действует как невидимый центр гидратации!

Будьте уверены, зная, что вы инвестируете в качество и надежность с кулером для воды IUISON под раковину. Изготовленный по самым высоким стандартам мастерства и долговечности, этот прибор создан, чтобы служить долго. От его прочной конструкции до надежной работы, каждый аспект кулера для воды IUISON под раковину разработан для долгосрочного удовлетворения. Поддерживаемый надежным брендом и отличным обслуживанием клиентов, это разумный выбор для требовательных домовладельцев, которые требуют только лучшего. Ощутите разницу с IUISON.

Оснащенный передовой технологией охлаждения, водяной кулер IUISON под раковину гарантирует, что каждый глоток будет освежающе холодным и удовлетворительным. Оснащенный высокопроизводительными холодильными компонентами, эта система быстро охлаждает воду до желаемой температуры, обеспечивая постоянный поток охлажденной воды, когда бы вам это ни понадобилось. Будь то наполнение стакана для быстрого питья или пополнение бутылки с водой на предстоящий день, вы можете рассчитывать на водяной кулер IUISON под раковину, который предоставит вам хрустящую, освежающую воду по запросу.

Испытайте высший уровень удобства на кухне с водяным кулером IUISON под раковину. Разработанный с учетом современных кухонь, этот инновационный прибор без труда интегрируется в вашу мебель, экономя ценное пространство на столешнице и обеспечивая мгновенный доступ к охлажденной воде. Скажите "прощай" громоздким диспенсерам для воды и "здравствуй" стильному, сдержанному дизайну, который улучшает эстетическую привлекательность вашей кухни. С его компактными размерами и стильной отделкой, водяной кулер IUISON под раковину является идеальным сочетанием формы и функции для современных домов.

Присоединяйтесь к движению за устойчивое развитие с водяным кулером IUISON под раковину. В отличие от традиционных кулеров, которые полагаются на пластиковые бутылки с водой или одноразовые стаканчики, этот экологически чистый прибор помогает сократить пластиковые отходы, предоставляя удобную и многоразовую альтернативу. С его встроенной системой фильтрации, водяной кулер IUISON под раковину обеспечивает чистую, вкусную воду прямо из вашего крана, устраняя необходимость в одноразовом пластике. Окажите положительное влияние на окружающую среду, наслаждаясь преимуществами гидратации с IUISON.

IUISON специализируется на коммерческих машинах для питьевой воды из нержавеющей стали SUS. За 16 лет работы в международной торговле мы заслужили прочную репутацию за поставку высококачественной продукции, отличного обслуживания клиентов и конкурентоспособных цен. Это позволяет нам предлагать индивидуальные решения, соответствующие уникальным требованиям наших клиентов.

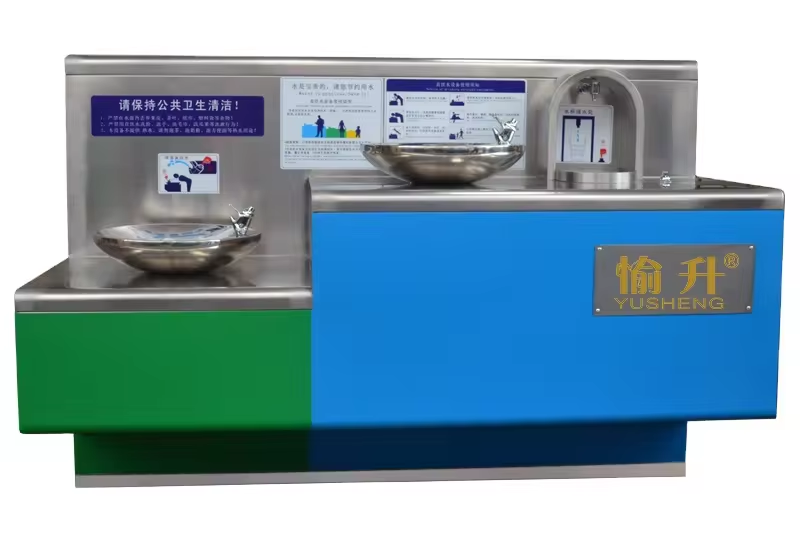

Наш портфель продукции включает водяные охладители, водонагреватели и настенные фонтанчики для питьевой воды, которые продаются более чем в 80 странах и регионах по всему миру, обслуживая крупные компании, государственные учреждения и международные экологические агентства. Наша годовая выручка от экспорта превышает 10 миллионов долларов.

Эффективный диспенсер горячей и холодной воды для офиса, с элегантным дизайном и простым обслуживанием.

Прочный нержавеющий стальной фонтан для улицы, обеспечивающий освежающее увлажнение для посетителей парка.

Компактный настенный фонтанчик, идеально подходящий для школ, простой в использовании и обслуживании.

Экономящее место охладитель под раковину обеспечивает мгновенное охлаждение воды с премиальной фильтрацией.

27

Apr

27

Apr

27

AprМы предлагаем множество различных водяных охладителей под раковину, которые различаются по емкости, дизайну и технологии охлаждения, среди прочего, чтобы они могли удовлетворить любые потребности или предпочтения наших клиентов.

Да, мы действительно допускаем настройку наших кулеров для воды под раковину. Мы можем внести изменения, такие как изменение размера, вариации цвета или даже дополнительные функции в зависимости от того, что вам нужно от вашего нового устройства, подобного этому!

Установка этих продуктов относительно проста; обычно все, что нужно, это нанять профессионального сантехника или мастера, который будет следовать инструкциям, предоставленным с каждым проданным нами устройством, но если потребуется, наша команда поддержки клиентов также будет более чем счастлива помочь им в течение их задачи.

Эти конкретные модели были сделаны легкими в обслуживании. Все, что нужно сделать, это регулярно чистить внешние части и, когда это необходимо, заменять фильтры (если применимо) – в руководствах по продукту содержатся рекомендации о том, как часто это следует делать, чтобы не ухудшить уровень производительности, достигнутый во время использования, а также обеспечить длительный срок службы.

Наши системы фильтрации первоклассные и эффективно удаляют примеси, что делает их безопасными для потребления, поэтому да; любой человек может безопасно пить из своей личной системы питьевой воды под раковиной.

Мы полностью уверены в наших продуктах, поэтому предоставляем широкие гарантии на все из них, но могут быть небольшие различия в зависимости от различных моделей, доступных в любое время, поэтому, если необходимо, пожалуйста, свяжитесь с профессионалом службы поддержки клиентов, занимающимся вопросами гарантии.